JIS F7307 Cast Iron Globe Valve

Material of Main Parts

Body: Cast Iron FC20

Seat: Bronze BC6

Disc: Bronze BC6

Stem: Brass C3771BD

Overview

The JIS F7307 standard cast iron globe valve is a critical device designed for precise control of fluid opening, closing, and flow rate within pipelines. Strictly adhering to the Japanese Industrial Standard (JIS F7307), it ensures reliability and interoperability in high-pressure, harsh environments such as shipbuilding, marine engineering, power plant systems, and industrial pipelines. Constructed from high-strength cast iron, this valve is ideal for applications requiring strict fluid shut-off due to its excellent durability, superior sealing performance, and long service life.

Why Choose Our JIS F7307 Cast Iron Globe Valve?

Compliant with International Standards: Designed, manufactured, and tested strictly according to JIS F7307 specifications, ensuring perfect compatibility with standard piping components.

Rugged and Reliable Construction: The valve body is made of high-quality cast iron, precision cast and machined, possessing extremely high mechanical strength and corrosion resistance, suitable for a variety of media.

Superior Sealing Performance: The valve disc and seat are ground and precisely matched, providing a bubble-level seal, effectively preventing internal and external leakage and ensuring system safety.

Superior Sealing Performance: Smooth and flexible operation: Utilizing a rising rod design with a trapezoidal threaded valve stem, opening and closing is effortless and precise, and it features an intuitive position indicator.

Wide applicability: Suitable for various media including water, steam, oil, and non-corrosive gases, with a wide operating temperature and pressure range.

How to Choose the Appropriate Specifications?

Please refer to the detailed size parameter table provided at the bottom of this page. When selecting, the main factors to consider are: pipe diameter (Size), working pressure (Pressure Rating), media type (Media Type), material and connection method. If you are unsure how to choose, please feel free to contact our technical support.

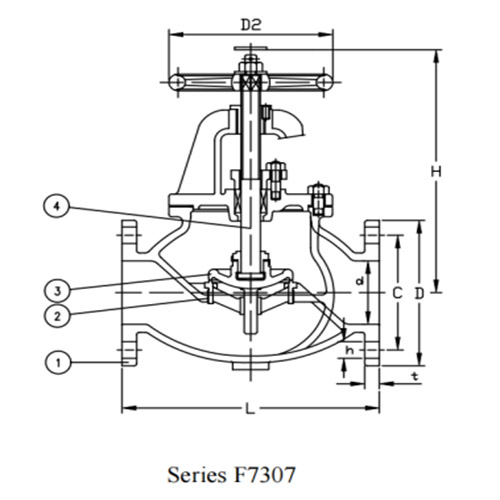

Reference Drawing

Main Datasheet

Size | L | D | C | No. | h | t | H | D2 |

50 | 220 | 155 | 120 | 4 | 19 | 20 | 285 | 160 |

65 | 270 | 175 | 140 | 4 | 19 | 22 | 310 | 200 |

80 | 300 | 185 | 150 | 8 | 19 | 22 | 320 | 200 |

100 | 350 | 210 | 175 | 8 | 19 | 24 | 370 | 250 |

125 | 420 | 250 | 210 | 8 | 23 | 24 | 420 | 280 |

150 | 490 | 280 | 240 | 8 | 23 | 26 | 470 | 315 |

200 | 570 | 330 | 290 | 12 | 23 | 26 | 555 | 355 |

250 | 740 | 400 | 355 | 12 | 25 | 30 | 680 | 450 |

300 | 840 | 445 | 400 | 16 | 25 | 32 | 770 | 500 |